Safeguarding Food Supply Chain

Implementing quality assurance in food supply chain starts at the farm with Good Agricultural Practices, Good Manufacturing Practices, Good Hygiene practices and Good Laboratory Practices. This enhances the production of food that is high-yielding, safe and has high nutritional value. These quality systems, which are environmentally sound, ensure appropriate handling, storage, shipping & labelling of the product and the consumer is assured that the food meets quality and safety standards in the entire "farm to fork" cycle.

-

Quality Assurance

Quality assurance (QA) is a way of preventing mistakes or defects in manufactured products and avoiding problems when delivering solutions or services to customers

-

Quality Policy

The laboratory incorporates a detailed Quality Policy.

- To ensure accurate and timely testing of raw materials, in -process materials and finished products and to continuously meet or exceed the stated or implied expectation of our clients through day –to-day interactions.

- Tests and calibration are always carried out in accordance with stated standard methods and clients requirements.Request to perform tests that may jeopardize an objective result or have low validity are rejected.

- Excellence in the work place is promoted by providing all employees with the knowledge, training and equipment necessary to allow for the completion of accurate and timely work.

- Personnel: Familiarize themselves with management system, documentation and implement the policies and procedures in their work at all times.

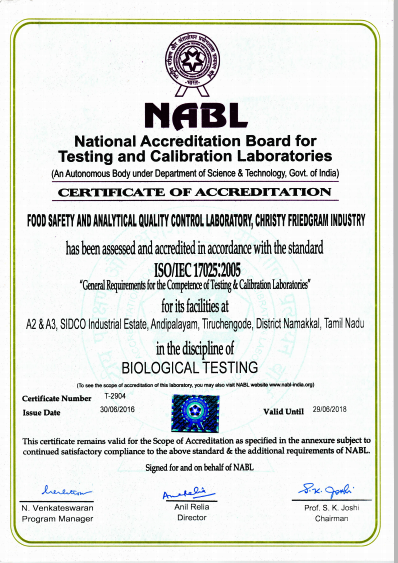

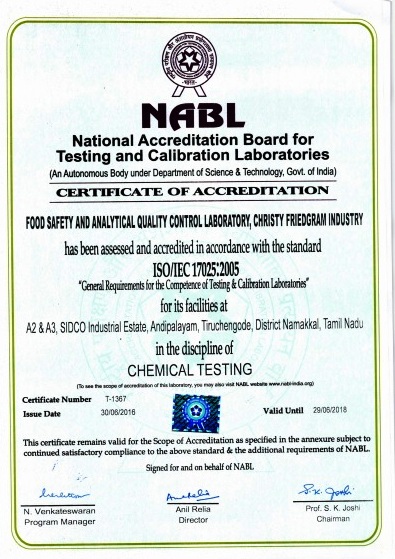

- The management is committed to complying with IS/ISO/IEC 17025 and this continually improves the effectiveness of the management system. This quality manual is to document the compliant policies and associated procedures that are integrated into our daily activities.